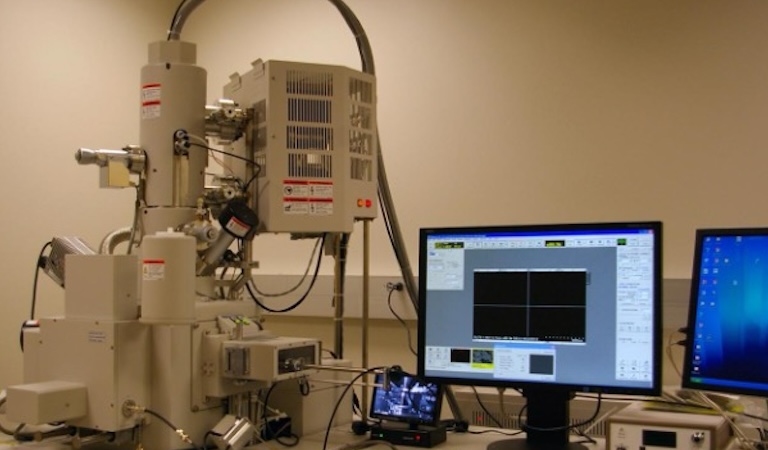

Scanning Electron Microscope

Harvey Mudd College operates a Hitachi SU-70 Scanning Electron Microscope jointly with Pomona College. This facility is the result of a joint National Science Foundation grant to faculty at both colleges.

Do you need to use the SEM for a project?

We will train one user per research group or clinic project per academic year. Complete the Scanning Electron Microscope Training Request (https://pomona.formstack.com/forms/scanning_electron_microscope_training_request) to start the process. Typical training consists of two two-hour sessions involving some direct instruction on our calibration samples, some video instruction, and finally some time spent on your sample. You should plan to come with a sample and describe that sample for us before the training. To be used in the SEM, the sample must be clean and dry. We have a way to pre-pump the sample overnight, if necessary, as well as a sputter coater if your sample is completely insulating and you want to make imaging easier. (This can greatly reduce the complexity of imaging some samples.) You should discuss with your advisor what conditions he or she thinks are best for your samples.

Only two people are trained in a session. Otherwise, no one gets enough time at the controls to get a feel for the instrument. Of course, this varies if some people have previous SEM experience and are simply learning our instrument in relation to one they already understand. Basic training will cover imaging only, but elemental analysis or lithography are possible with future training sessions for advanced users.

There are no charges for local users at this time, but we require all users to submit a report to us sharing some of their best images along with a description of how they were used in support of the research project. This helps us to enable future funding. We also will ban users who do not conform to our rules and regulations. This is a necessity for us to maintain low overhead and trouble-free operation.