HMC Students are Building an Airplane

November 15, 2018

Harvey Mudd College students are preparing for takeoff—with a plane they built in the basement of the Parsons Engineering Building. David Harris, an engineering professor, has assembled a team of more than 50 students to assemble a Vans RV-7A Aircraft.

Harris, the Harvey S. Mudd Professor of Engineering Design, initiated the project during the 2017–2018 academic year, recruiting Harvey Mudd students and building a team. The project attracted many first-year students because it does not require prerequisite coursework.

To begin, the team set up shop facilities, acquired tools and learned sheet metal techniques. The students worked as a team to design custom sensors and an augmented reality system for the project.

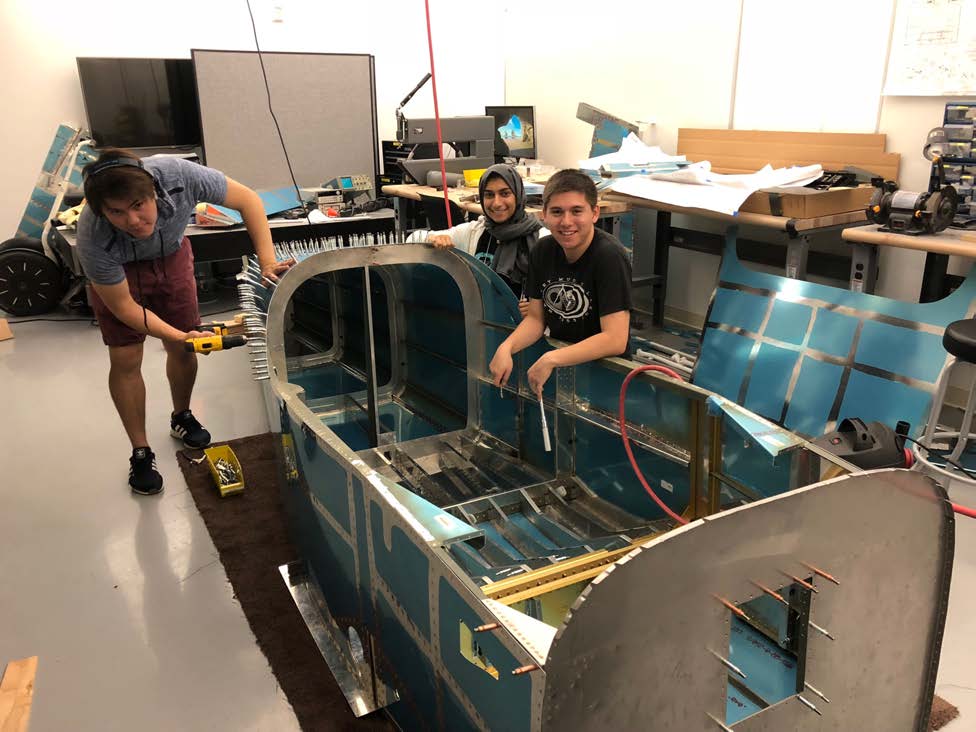

Summer 2018 student interns (left to right) Roger Hooper ’19, Reem Alkhamis ’21, Jonathan Schallert ’20 and Curtis Shinn ’19 with the wing skeleton in the Parsons Engineering Building Aero Lab.

Aside from the technical hands-on work, the students are gaining professional skills, including teamwork and problem solving.

Reem Alkhamis ’21, Roger Hooper ’19, Jonathan Schallert ’20 and Curtis Shinn ’19 worked full-time on the airplane as interns over the summer of 2018 with the help of Alex Mouschovias, a pilot and Clinic liaison from Niagara Bottling. Additionally, Harris recruited seven high school students from the Scripps College Academy STEAM Program. Seven children and grandchildren of Harvey Mudd faculty and staff also worked on the project, along with three of their friends.

Harris chose a Vans aircraft kit because it is considered easier to assemble than other models on the market, is more efficient and has a good safety record.

“The assembly steps are reminiscent of a giant Lego project for adults,” Harris says. He gives students opportunities to work on the pieces of the plane they are most interested in.

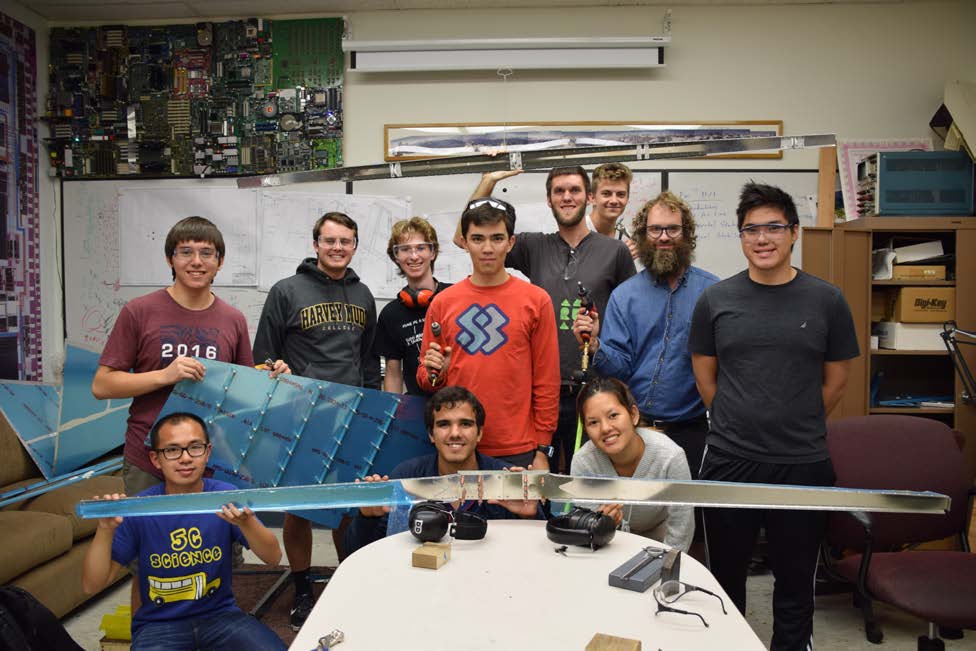

Roger Hooper ’19, an engineering major, drilling fuel tank brackets in the Aero Lab.

“When I was working on the plane over the summer, Professor Harris observed that I did the best work when I worked on a small part by myself,” says Hooper, an engineering major, who, like most of the students, finds the work challenging. He worked on the fuel tanks, which have to be simultaneously assembled and sealed. On his initial try, the fuel tanks leaked when pressurized, and Hooper says he had to use trial and error to get them sealed properly.

“As the students’ skill level has increased, the directions have become skimpier, keeping the level of intellectual challenge fairly constant and the ratio of thinking to building at roughly one to one,” Harris says. “The later stages of painting, wiring and plumbing are nearly all done from first principles with very few hints.”

After finishing the tail component, another summer task was assembling the wings and the fuselage of the plane.

“The most rewarding part of the project was getting to see the entire plane come together,” Hooper says. “We hadn’t had the chance to mount the wings to the fuselage like we had hoped, but there was enough there to make it look like an actual plane was sitting in that room and it made me feel really good knowing that my hands took part in building it.”

(Left to right) Curtis Shinn ’19, Reem Alkhamis ’21 and Jonathan Schallert ’20 working on the fuselage in the Aero Lab.

A new team of first-year students joined the project in fall for the 2018–2019 academic year.

As of October 2018, the team had logged over 2,700 hours working on the airplane. Harris estimates they are comfortably over halfway done with the build. Generally, this type of aircraft would take one person 1,800 hours to complete, however the goal is to give all students on the team the opportunity to learn and complete tasks correctly as opposed to building quickly.

Harris plans to have two students working full-time during summer 2019 to install the engine, avionics and associated plumbing and to complete the airplane. The plane will be moved to the Cable Airport in Upland for completion and flight testing.

The airplane will hold two people and cruise at about 190 mph. The team will use the aircraft to log data on acceleration and strain, and will share this data with Vans Aircraft for fatigue analysis. They will also continue to use the airplane to experiment with augmented reality for general aviation.

“I am always looking for opportunities to learn more and gain more experience in aerospace, so I was naturally drawn to Professor Harris’ airplane project,” Hooper says. “How could I pass up the opportunity to take part in building an airplane with my own hands?”